Setting the joints on FireCrunch is a simple process. It is very similar to standard plasterboard joint setting, however there are a few things to note.

Base Coat – Use Pro Plaster PRO BASE 40 faster 40 minute set. (warranty). This is a specifically formulated extra bonding adhesive for embedding paper tape to FireCrunch Joints and internal angles.

Base Coat – Use Pro Plaster PRO BASE 40 faster 40 minute set. (warranty). This is a specifically formulated extra bonding adhesive for embedding paper tape to FireCrunch Joints and internal angles.

Tape – Use paper tape internally not fiba fuse types. External see Fire jointing instructions and use fire sealant on external wall joints. Do not use the fire sealant between internal board joints, just run 3 beads of fire sealant down face of internal stud faces prior to fitting boards, set to 1 mm pressured sealant fit, screed off excess with damp cloth.

Fire Sealant Internal walls K-Clad TE10 ( AS1530.4 type ) will take 24 hours to cure. Ensure all internal perimeters of the internal wall are fire sealed if part of an FRL rating IE 30 60 or 90 minutes.

- See internal wall manual and main fire manual.

MgSO4 materials are more absorbent than plasterboard, on warm days ensure rebated joint areas are well soaked with water prior to setting base coats and tape, to counter the higher absorption rate of the MgSO4 board, do not dry set joints to avoid cracking USE the Pro Base 40 only (warranty).

- Sealing boards and painting after plaster set see Prime & Painting Manual.

Fire Manual

For warranty instructions on plaster setting base coats tape and joints.

Preparation

Pro Plaster base compound Pro Base 40 and 4T Topping compounds should be stored at room temperature for at least 24 hours prior to use. Mix lightly and test apply. Do not over mix as this can cause pocking. Add water 250 ml at a time as necessary; remix and test apply before adding additional water.

Application

Any surface imperfections or damage that may have occurred should be repaired to the board surface prior finishing. Apply over dry surfaces only and allow each coat to dry completely before applying another coat. Maintain minimum air, joint compound and surface temperature within working area until joints are completely dry.

Class 4/5 Finishes

To obtain a class 5 finish mix an amount of 4 x diluted mix of plaster base coat and either roll or spray on the installed sheets. Apply light fine grade sand after 24 hours which will produce a class 5 finish.

To obtain a class 5 finish mix an amount of 4 x diluted mix of plaster base coat and either roll or spray on the installed sheets. Apply light fine grade sand after 24 hours which will produce a class 5 finish.

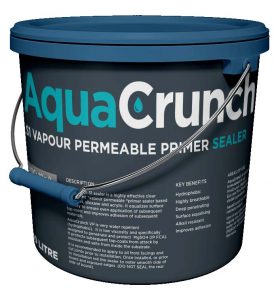

Note: After the total finished plaster set is completed it is essential (warranty) to roll on the Vapour permeable clear sealer Klaas Si AquaCrunch, before applying recommended DULUX Precision, max adhesion under coat and then finish, with DULUX recommended tested water based paints (system).

General Information / Hand Tool Application

Special important note

Magnesium oxide boards are more absorbent than plasterboard. Ensure each rebated edge is well soaked by generously sponging prior to each joint being set and only use the Pro Base 40 minute faster set base coat compound (Warranty)

Embed “plasterers paper tape” to the FireCrunch board; make sure no fasteners protrude above the FireCrunch panel surface using a broad steel finishing knife.

Use Pro Plaster Pro Base 40 taping compound to fill the channel formed by the rebated edges of the FireCrunch Centre and lightly press paper tape into fresh joint compound. Working within a convenient arms-reach area embed tape by holding knife at an angle to panel, draw knife along joint with sufficient pressure to remove excess compound, above and below tape and at edges.

Leave sufficient compound under taper for proper bond, while embedding, apply a thin coat of Pro Plaster Pro Base 40 compound over the tape. This thin coat reduces edge wrinkling or curling and makes the tape easier to conceal with following coats. Allow to dry completely.

Fill Coat Application

After the Pro Plaster tape embedding coat is dry, apply a topping using Pro Plaster 4T Multi Purpose or similar approved compound, fill second coat approx 180mm to 250mm wide over taped joint. Feather edge of second coat 50mm beyond edge of first coat. Allow to dry.

Finish Coat Application

After second coat is dry, apply a thin finish coat of 4T Multi Purpose Compound over joints. Finish compound, should be applied at a slightly thinner consistency. Feather edge of third coat at least 50mm wider than second coat.

Finishing Inside Corners

Apply a thin layer of compound to either side of the corner. Crease centre of tape and press into corner. Tightly embed tape with knife on both sides removing excess compound and apply it as a thin coat over tape. Apply second coat over one side at a time allowing it to dry before finishing opposite side.

Sanding Application

Light sand with a wet sponge to eliminate dust and scuffing . Remove high spots using as few strokes as necessary. Clean sponge often. If dry sanding, use 180 grit sandpaper or finer. Avoid scuffing tape.

If dust is generated wear suitable protective clothing including PVC gloves (AS 2161), Eye protection (dust resistant AS/NZS 1336), and a respirator (AS/NZS 1715 and 1716.Wash clothes regularly.

On completion of all plaster set and ready undercoats use only Klaas Si AquaCrunch vapour permeable sealer on FireCrunch MgSO4 sheets.

Klaas Si AquaCrunch “vapour permeable” primer sealer (Warranty) see recommended products. Available from sales@firecrunch.com.au

Warranty

FireCrunch will not be liable for incidental and consequential damages, directly or indirectly sustained, nor for any loss caused in application of these materials other than to the manufacturers specified instructions. Our liability is expressly limited to replacement of defective goods.

Any claim shall be deemed waived unless made in writing 7 days (7) days from the date it was, or, reasonably should have been discovered following delivery of the FCA products. Photo POD will be in evidence and once picked up by carrier the damage liability rests with purchaser.

Health and Safety

For further health and safety handling instructions, refer to the (SDS) Safety Data Sheets for these products.

Yes. FireCrunch is not that dissimilar to fibre cement board when it comes to uses.

FireCrunch has been trialled with budget tile adhesives and worked perfectly.

No special tools are required to use FireCrunch.

It can be sawn, drilled, screwed and planed just like timber. USING TIMBER TOOLS.

It is recommended that screw fasteners, not stud adhesives, are used when fixing the sheets in the wet areas of steel and timber framed buildings.

FireCrunch is easy to work and machine with normal woodworking tools and equipment. Cut sheets with a fine tooth handsaw or power saw. Edges may be trimmed with a smoothing plane, power plane or sandpaper.

Panels with thicknesses 10mm and under can be deep scored with a cutting knife and snapped along the straight edge in the same way as you would with gypsum boards.

Where holes are required clean cutter bits or twist drills are satisfactory.

Woodworking shapers, spindle moulders and high speed routers may be used to shape or mould the edges of FireCrunch. Tungsten carbide tipped cutters are preferred for long production runs.

Note: FireCrunch does not require the use of expensive countersinking to fix which takes extra time time and requires expensive tungston tipped drills and saws. As with CFC cement sheeting and is some 35% less in price.

Yes.

FireCrunch is NATA Labs CSIRO Fire Certified to Australian standards and also complies with the following sections and volumes of the BCA (Building Code of Australia), ABCB Canberra and NCC National Construction Code.

- BCA Volume 1 Section C FRL (Timber Frame 60/60/60 Metal frame 90/90/90) Load bearing and( Non Load bearing FRL -/120/120. *** Fire ENG/ assessment / NCC

- BCA Volume 2 Part 3.5.3.3 Fibre cement planks and weatherboard cladding.

- BCA Volume 2 Part 3.5.3.4 Fibre cement sheet wall cladding.

- BCA Volume 2 Part 3.5.3.5 Eaves and soffit linings.

- BCA Volume 2 Part 3.7.1 Fire separation for FRL to (Timber frame 60/60/60 Metal frame 90/90/90) Non load bearing FRL -120/120.

*** Denotes see specific instructions re these rates of FRL for timber as the FRL varies according to steel frame BMT or timber type.

- BCA Volume 2 Part 3.7.4 Bushfire areas including all state variations to Part 3.7.4.0 and 3.7.4.1 as

tested under AS 1530 parts 8.1 and 8.2. BCA Volume 2 Part 3.8.6, Sound insulation to Rw +Ctr 62.

CSIRO CERTIFIED AS/1530.4 (DTS) and NCC alternative performance solutions. See certifications. - AS1530.1

- AS1530.4

- AS 5367

- AS 3837

- AS1530.8.1

- AS1530.8.2

- AS 3959

- AS 717

- AS 4964

Yes, we do.

Installation manuals can be found under Manuals & Drawings.

Internal Walls / Floors / Ceilings / Wet Areas / Fire Rated Areas

Priming sealing before painting or rendering.

FireCrunch must always be sealed and finished regardless of where or how it is used, however this is particularly important in areas of high humidity. Extra care must be taken to ensure the board is sealed correctly on the face, top and exposed edges, leave the inner back rough side of board unsealed.

All FireCrunch MgSO4 composite fire boards must be pre-sealed with Klaas S1 AquaCrunch (vapour Permeable” prime sealer. Failure to use this product before painting or rendering will void the warranty. Available direct wholesale from FireCrunch (Ask us).

FireCrunch will not attract mould or mildew and bacteria cannot survive on (MgSO4).

Correct preparation and sealing will ensure a long life for your building.

FireCrunch differs from plasterboard in a number of ways in that it is:

- Approx. ten times stronger

- It won’t degrade in water*

- It cannot be eaten by termites so totally protects timber framing

- Is easier to handle and use (less chance of board damage)

- Can be used as both an indoor and outdoor lining

- Improves the thermal and sound insulation of your project

- Acoustics are Rw 62 plus ctr =net Rw52

- BCA requirement Rw 50 net

- 90mm frame cavity using appropriate ( Mfg) insulation batts FRL 90/90/90

- Is virtually fireproof (CSIRO certified). See Certifications (FRL 30/30/30 to 90/90/90)

* Warranty: Prolonged submersion in water without an opportunity to dry out will void the FireCrunch warranty. Before using, treat this product as an indoor product: store out of weather, under cover, prior to sealing with (“Vapour Permeable Sealer”) Klaas S1 AquaCrunch.

Do not use regular undercoating direct to the board surface otherwise paint surfaces will be affected. Once sealed with above vapour permeable sealer after 24 hours apply Dulux Precision, Max Adhesion Primer then use Dulux Finish water based paints ( Warranty tested product).

Do not use regular undercoating otherwise paint surfaces may be affected, use standard water based paints when pre sealed.

Although FireCrunch does not degrade in water it should not be left out in the rain as there will be a low % of HYDRATION IE, absorption of water. If this does happen the board will have to be dried out before use… drying out the board will not cause warping or any loss of integrity.

FireCrunch should always be stored flat in a dry undercover space on a horizontal pallet or on supports spaced at 450mm centres. It should not be stored laid directly on the ground.

AND DO NOT LEAVE THE BOARD HANGING OVER THE PALLET EDGES OR GLUTS OVER 450MM IT MUST BE SUPPORTED FLAT as all time prior to use.

Always handle with at least one person at each end of the board. With hands apart, lift the board and tilt to prevent sagging. (See data sheet for more information).

FireCrunch is more expensive than plasterboard due to the additional properties that make FireCrunch a superior lining product.

We cannot give you price variations here as plasterboard prices vary between suppliers, however, the cost of maintaining plasterboard in the long term well outweighs the cost of installing FireCrunch to begin with. Plus only 1 layer of 10mm FCA equals 3 layers of 13mm for 90 minutes in fire.

Yes.

FireCrunch is recyclable, contains no toxic chemicals, FORMALDEHYDE, ASBESTOS OR VOC (Ask us for copy SDS or see Certifications, Australian Govt legal requirement) support@firecrunch.com.au or call 1300 933 102.

FireCrunch has one tenth the carbon footprint of fibre cement plasterboard and due to the need for less repair, has less wastage. During the manufacturing process, in carbonation, FireCrunch draws back 90% of the CO2 used in manufacturing and makes it a virtually carbon neutral product. Any waste is just ground up and reused.

Only 1% wood chip used in FireCrunch products, eliminating the destruction of millions of oxygen generating, CO2 absorbing green trees in the manufacture of paper lined plasterboard. Choose FireCrunch, an environmentally responsible cladding product.

FireCrunch has a very high fire resistance and has been tested at temperatures up to 1200ºC for over four (4) hours and board did not ignite or pass flames) CSIRO.

FireCrunch passed the following BCA ABCB AND NCC tests in 2015, re-assessed July 2020 to 2025.

- AAS1530.1 Non-combustible building cladding

- AAS1530.4 Fire resistant systems tests in timber and steel framing load (55Kn) and non-load bearing

- AS 5367 Non-flash over and (RISF) Resistance to Incipient spread of flames 60 minutes and 90 minutes

- AS 3837 Smoke release and pre-ignition tests

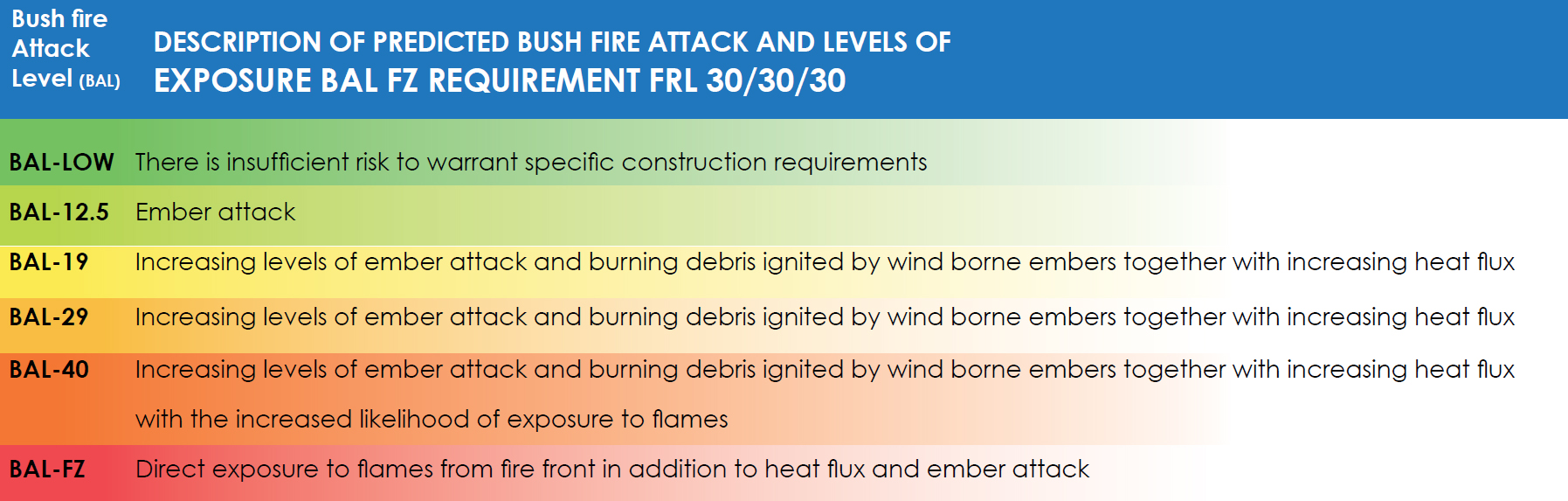

- AS 3959 Bush fire standard for all BAL FZ flame zone

- AS1530.8.1 and AS1530.8.2 BAL FZ post-fire re-ignition standard compliance

- AS 4964 Non-asbestos content (border security) NATA Labs

- No Chloride tests NATA Labs Sharpe and Howells VIC

- Load bearing span tests to 6.1 kN 19mm TG sheets NATA Labs Brick and Mortar VIC

(CSIRO) CERTIFICATION

AS 1530.4 / 2015 RE ASSESSED JULY 2020 TO JULY 2025

Methods for fire tests on building materials, components and structures, Part 4: Fire-resistance test of elements of construction covering fire resistance.

(CSIRO full, real-time external area bushfire simulation test)

AS/NZS 1530.8.2 see burn down attempt CSIRO 2017.

Methods for fire tests exclusively for materials and elements of construction in bushfire-prone areas, namely:

- AS 1530.8.1 – Tests on elements of construction for buildings exposed to simulated bushfire attack;

- Radiant heat and small flaming source, which covers BAL 12.5 to BAL40

- AS 1530.8.2 – Tests on elements of construction for buildings exposed to simulated Bushfire attack.

- Part 8.2: Large flaming sources, which covers BAL-FZ FRL 30/30/30. (All contained within the AS 1530.4-2014 certification),which is 90 minutes not 30 mins using. Just 1 x single 10mm sheet each side of single frame.

Fire resistance level (FRL) 90/90/90

- Load Bearing

- Steel Frame: 90/90/90 55kN

- Timber Frame: 60/60/60

- Non Load Bearing: -/120/120 higher FRL with 2 x 10mm each side1.15 BMT

- FireCrunch IS CSIRO Certificated on a 90mm cavity standard steel frame with just 1x 10mm

- FireCrunch board each side of frame with R2.5 glass wool batts for FRL 60 minutes and 80Kg mineral wool batts for FRL 90 minutes and to achieve acoustic rating Rw62 Plus ctr net Rw52 .

Australian certified testing NATA LABS CSIRO available (ask us) or for download. » See Certifications.

Yes.

FireCrunch has a high sound insulation rating : Rw62 PLUS ctr NET Rw 52.

FireCrunch exceeds BCA minimum requirements for airborne sound insulation between walls AS 717. See Certifications.

Yes.

Termites, one of the worst contributors to home damage, have no interest in FireCrunch, they cannot consume it and are repelled by (MgSO4) TOTAL PROTECTION FOR EXPENSIVE TIMBER FRAMING.

No.

FireCrunch contains no formaldehyde, no asbestos and no toxic chemicals or CORROSIVE MAGNESIUM CHLORIDE. FireCrunch uses Magnesium Sulphate (MgSO4) being a non-corrosive element and in this regard is unique at present in Australia ( NO VOC).

Standard FireCrunch is a water resistant product before sealed, in that it does not retain water if unsealed in warm weather it will release moisture.

This means that an “unsealed board will absorb some moisture in damp or wet areas” if left unsealed. You should not expect the board to hold it’s integrity if submerged in water or exposed to multiple wet/dry processes, before use, particularly without adequate MgO sealing.

Use special MgSO4 “vapour permeable Sealer” (See Recommended products). Klaas AquaCrunch S1. (Supplied by FireCrunch).

FireCrunch should not be left out in the rain before sealing /priming. MgSO4 Sealer (See Recommended products)

Because FireCrunch is a breathing permeable board it will hydrate when not sealed. However, if inadvertently left in the wet or in exterior weather, move it to a dry environment with separated sheets. FireCrunch will dry out quickly without swelling or warping and hold it’s strength integrity.

FireCrunch that has been installed externally and not pre sealed could crack at fixtures due to residual moisture in the board being removed in the drying process, especially when exposed to multiple wet/dry processes.

Best practice:

- Store undercover on delivery to site before use. Do not attempt to paint if board wet

- Allow to dry completely before sealing painting or rendering, hydroscopic level under 10%.

- FireCrunch board called (Type FCA) is sold in 10mm K-Clad SE AND TE 10

- For flooring, K-Floor 19mm TG Tongue and Groove

- For exterior walls in a Bushfire K-Clad flat finish or K-Wall a timber appearance groove / weatherboard TS12 2700×1000 x12mm

- In Decking 16mm K-Deck TG Decking Groove boards for exterior decking

- 19mm TG 27000×600 is also used for bushfire roofing substrate eliminating expensive 15mm marine ply (which is actually combustible

and does not now have a AS1530.1 certificate) So should NOW never be used in Bushfire areas ( NCC 2019 revisions) combustible material.

16mm FIreCrunch is designed for internal/external use so is the best choice for decking and external applications.

Pre-seal FireCrunch boards with MgO primer sealer Klaas S1 AquaCrunch. (See Recommended products)

And use Dulux Precision MAX adhesion undercoat and Dulux hard wearing decking paints, to choice of timber colour.

Yes.

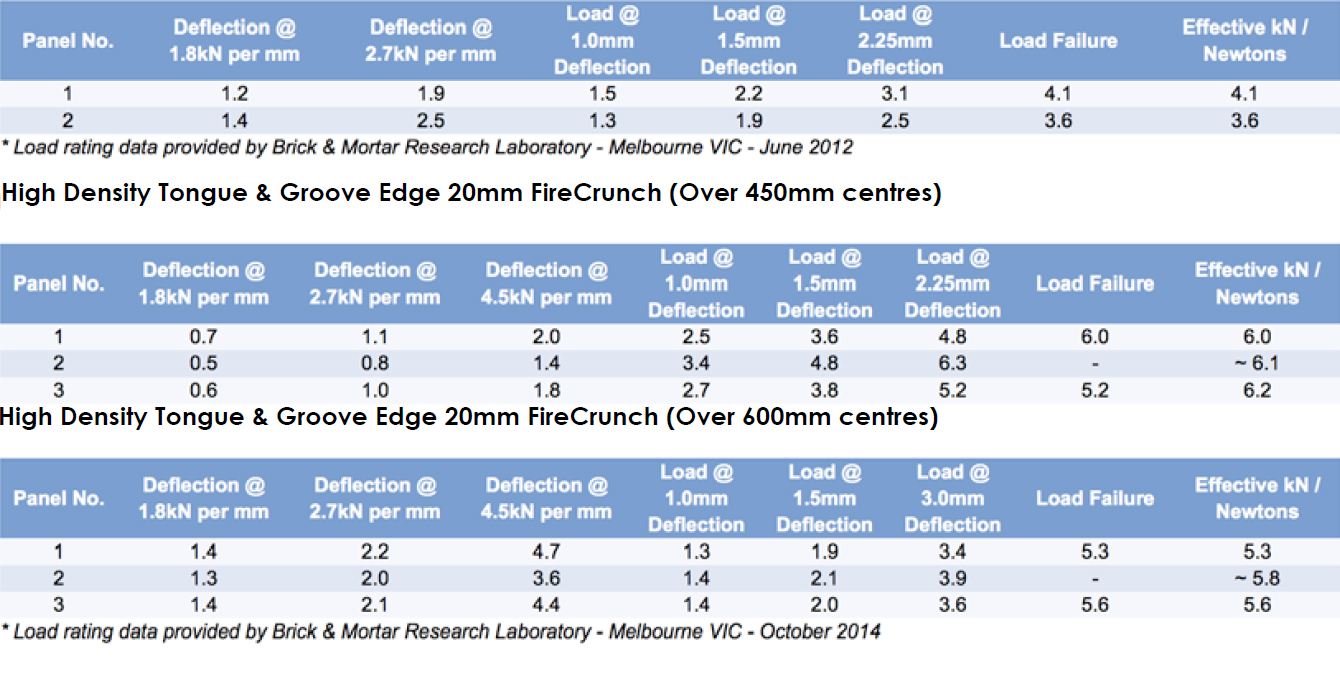

Tests have been carried out at the NATA Brick & Mortar Research Laboratory in Melbourne VIC.,an Australian NATA Labs testing authority

TESTED Standard Square Edge 19/20mm FireCrunch (Over 450mm AND 600 CENTRES 5.3 AND 6.2 kN, the TG board will of course rate higher

FireCrunch must not be nailed, using hand hammered nails, this will void the warranty. Power driven nail hammers can be used however, always extra screw fix the 4 corners and board centres, and as well use corrosive proof galvanised nails only.

Take note of the recommended screws that must be used. (See Manuals & Drawings)

FireCrunch Australasia warrant the board only when the correct screws and system manuals are adhered to. (See Recommended Products).

Screw Fixing

Steel frame: For screwing FireCrunch panels to steel framing, we recommend using ribbed head bugle self countersinking screws available from all major hardware stores.

Timber frame: For screwing FireCrunch panels to wood framing we recommend using stainless steel (or suitably corrosion protected) 8-10 Countersinking Ribbed Head Class 2 / 3 screws (depending on timber hardness).

FireCrunch exceeds BCA minimum requirements for airborne sound insulation for a wall between attached dwellings or intertenancy walls and meets the highest possible AAAC acoustic rating of 5 stars.

BCA Compliant Rw 62 plus ctr =net Rw 52 on DOUBLE STUD DISCONTINUOUS FRAME 76MM and 90MM Ask us for AS 717 certificate BCA Volume 2 Part 3.8.6 – Sound insulation to Rw62 Plus +Ctr net 52.

FireCrunch is made up of a combination of primarily Magnesium Oxide (MgO) and special non-metal corrosive magnesium sulphate Magnesium Sulphate (MgSO4)

NEW TECHNOLOGY 2018

FireCrunch is made up of a combination of primarily Magnesium Oxide (MgO) and Magnesium Sulphate (MgSO4) This has been bonded with a small percentage of organic and IP composite materials, strengthened with fibre mesh.

MgSO4 is a new development in the FCA range and replaces Mag chloride ( MgChl2) with Mag sulphate and eliminates all metal corrosion, a common problem with ordinary MgO chloride boards (MgChl2).

What is Magnesium Oxide?

MgO or Magnesium oxide (sometimes called magnesia), is an absorptive solid mineral, white in colour, that occurs naturally in metamorphic rocks and is sourced from magnesium mining. Magnesium oxide is a waste by product of external use process in steel manufacturing .

ENVIRONMENTAL — FCA is 100% better

FireCrunch is produced by the addition of magnesium sulphate to the mag oxide and lime followed by a heat process using low CO2 kiln temperatures, 50% LESS than plasterboard products, so 50% less CO2.

During the carbonation process of manufacturing, FireCrunch draws back 90% of the 50% CO2 created to produce FCA and makes it a virtually carbon neutral product!

Further, FCA eliminates the “additional destruction“ of millions of oxygen producing trees each year to manufacture weak ineffective low R value insulation, paper lined plasterboard and protecting them from termites, floods and fire!

FireCrunch has:

- Load bearing (steel frame FRL of 90/90/90 55Kn/ NATA LABS CSIRO NSW

- Load bearing (timber frame FRL of 60/60/60 NATA LABS RESOLUTE QLD

- on Load bearing FRL of —/120/120 more on application of additional 10mm sheet per side

!! Read timber framing specs for FRL 30/30/30 (Bush Fire Manual) and FRL 60/60/60 (Main Fire Manual) before commencing work on any firewalls.

» See technical manuals

» See certifications

The Building Code of Australia (BCA) defines the Fire Resistance Level (FRL as the testing period in minutes for three criteria, i.e.:

- 60/60/60 first figure is Structural Adequacy (the ability of a structure to maintain its stability and

load bearing capacity) - 2nd figure is Integrity (the ability of a structure to resist the passage of flames and hot gases)

- 3rd figure is insulation (the ability of a structure to maintain a temperature below specified limits on the unexposed surface

- being 180 Deg c plus ambient as a maximum allowed at any one point of the unexposed side of the fire wall).

The longest test time recognised by the BCA is 240 minute period 4 hours.

All FireCrunch products have been NATA tested or assessed under NCC 2019 by Registered Fire Engineers ( NCC 2019) and 2022 valid to until 2025, the 5 year limit for re evaluation.

The R-value of FireCrunch is a measure of its thermal resistance. The higher the numbers the better the insulator.

R-value is measured as m2/K/w

The values for FireCrunch are:

10mm FireCrunch = 0.066 m2K/w

19mm FireCrunch = 0.132 m2K/w

So the 10mm board has an R Value of 0.066

For example:

To work out the approximate R-value for a wall with a layer of 10mm FireCrunch each side of the stud with a R2.5 batt between them –

10mm FireCrunch + Batt + 10mm FireCrunch = Wall R-value therefore 0.066 + 2.5 + 0.066 = 2.632 (So the approximate R-value for the wall would be 2.6)

Please note that the above is just an approximate guide. Actual figures would have to be calculated. There are a number of on line calculators that can do this for you.

You should do all you can to prevent FireCrunch getting wet before installation as there will be some water absorption. If this happens, don’t worry, it just means you will need to separate the hydrated boards from each other and allow to dry in a sheltered warm space, preferably with low humidity. The boards will not be damaged or degrade if handled correctly. Once dry, install and immediately before or after installation seal the exposed face of the board with the recommended “MgSO4 primer sealer – see recommended products. Once sealed you must use a undercoat that is part of the Dulux System paint method.

Recommended is Dulux Precision MAX ADHESION primer UNDERCOAT then use their recommended water based finish paints.

The FireCrunch standard range of sizes is as follows:

| Product | Thickness | Width/Length | Type | Weight | Usage |

|---|---|---|---|---|---|

| K-Clad Interior/Exterior | 10mm | 2400 x 1200 | SE/TE | 28 | Fire finish walls & ceilings |

| K-Clad Interior/Exterior | 10mm | 2700 x 1200 | SE/TE | 34 | Fire finish walls |

| K-Clad Interior/Exterior | 10mm | 3000 x 1200 | SE/TE | 37 | Fire finish walls |

| K-Wall Interior/Exterior | 12mm | 2700 x 1000 | TS | 36 | Groove board, weather board |

| K-Deck Interior | 16mm | 2700 x 600 | T&G | 32 | Decking board |

| K-Floor Interior/Exterior | 19mm | 2700 x 600 | T&G | 35 | Flooring & roofing |

FireCrunch 16mm TG is for exterior decking groove board. 19mm TG is ideal for flooring and for roof fire protection in bushfire areas to BAL FZ, over trusses before steel or tiled roofing installed.

FireCrunch is produced in FIVE different thicknesses and 4 edge types: 10mm, 12mm, 16mm and 19mm TG which cover most 80-90% of all fire requirements.

There are also a few different types of edges for different types of application. Sheets suit floors, walls interior and exterior, ceilings roofing and decks.

To simplify this, please view the charts on the specific product(s).

Important information before painting or rendering FireCrunch MgSO4 cladding.

FCA Magnesium boards require special attention to priming undercoating and painting under strict warranty provisions.

- Use roll on Klaas S1 AquaCrunch primer sealer

- Use Dulux Precision MAX adhesion primer undercoat

- Use any recommended Dulux water based paint finish or Dulux hardware decking paints

Although FireCrunch tends to perform very well with most standard products, drying times may vary. All standard type renders can be used with FireCrunch, Render Systems Australia. Check suppliers instructions.

Render Systems Australia – Multiple Render Products

Pro Plaster base TRADES 40 and – 4T Multi-Purpose topping compounds “must be used with FCA” to retain the warranty, other manufacturers products will not be warranted with FCA products. Set in usual way but use only paper tapes for interiors and exteriors to Pro plaster Mfg specs.

FireCrunch has warehouses in NSW, QLD, VIC (with supply to ACT ex Sydney) and TAS, SA, WA and NT from Melbourne by road rail and sea links.

FireCrunch is a life saving fire composite sheeting and requires specific instruction to install to the Australian Fire Standards tested and cannot be sold over retail counters.

FireCrunch is not a DIY product and all installs must be carried out or overseen by a registered Trades Licensed holder in the state of installation who will be a joint signatory on the FireCrunch Warranty document.

National and all location enquiries to 1300 933 102 or to support@firecrunch.com.au or sales@firecrunch.com.au for further information.