Two major international corporations select FireCrunch products

Amazon Fulfilment Centre Jandakot, Perth WA

FireCrunch Australasia PL are manufacturers and suppliers of the lowest new CO2 pollutive cladding in Australia.

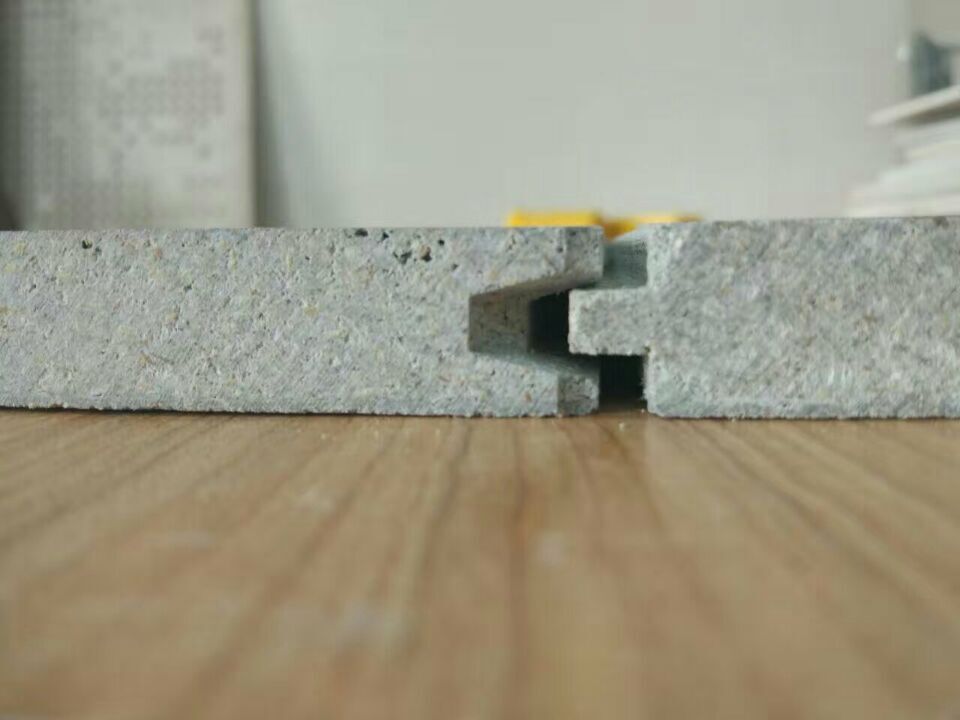

FireCrunch announces it was granted the 14,000 m2 mezzanine flooring supply contract via Dematic Pty Ltd – the supplier and installer of the automated computer-driven conveyor equipment for Amazon’s new warehousing fulfilment centre in the Airport Industrial Complex, Jandakot, Perth WA 2023.There were 9600 custom sizes cut, 19mm thick tongue and groove flooring sheets filling 17 containers with numbers and area code, floor location identification for installation.

FireCrunch TG 19mm met a specific high range specification capability in material density, weight and masonry screw and blind bolt pull through capability. This was required for the Dematic conveyor machinery installations, coupled with the essential, high FRL fire ratings required, with fire testing by NATA Labs CSIRO Infrastructure Technologies NSW, ISO 17025.This specification was not available in fibre cement sheeting like Scyon and particularly not the low net 5% CO2 levels in which CFC contributes 95% more CO2 pollution in manufacturing than (MgSO4) magnesium oxide materials (New Scientist/USA). ALL CFC products are high level CO2 polluters.

These NATA Labs high FRL fire tests in Australia demonstrate a single 10mm FireCrunch cladding sheet to withstand 90 minutes at 1000 deg C and 2 layers 10mm for 120 minutes versus 2 and 3 layers respectively of 16mm Fyrchek plasterboard. The 19mm TG flooring also to FRL 90/90/90.Thus saving a minimum 50% of the cost of material supply, site handling labour, 50% less crane up and 50% less freight costs all Increasing ROI in all cases, as responsible industry leaders move toward lower net CO2 materials, in reaching towards the 2030 and 2050 Accords.

FireCrunch cladding chosen for Govt. RAAF personnel accommodation units Sydney

These units are the first of a new high-speed steel-framed pre-fabricated modular accommodation production system for the RAAF in Sydney.

This new construction system has lowered costs and speeded up output.

FireCrunch single 10mm K-Clad sheets afforded both FRL 90 90/90 and assisted the acoustic well over plasterboard and at 50% of the normal fire wall cost in 50% less product, 50% less freight cost, 50% less crane up, 50% less site labour handling all helping increasing ROI and deadlines.

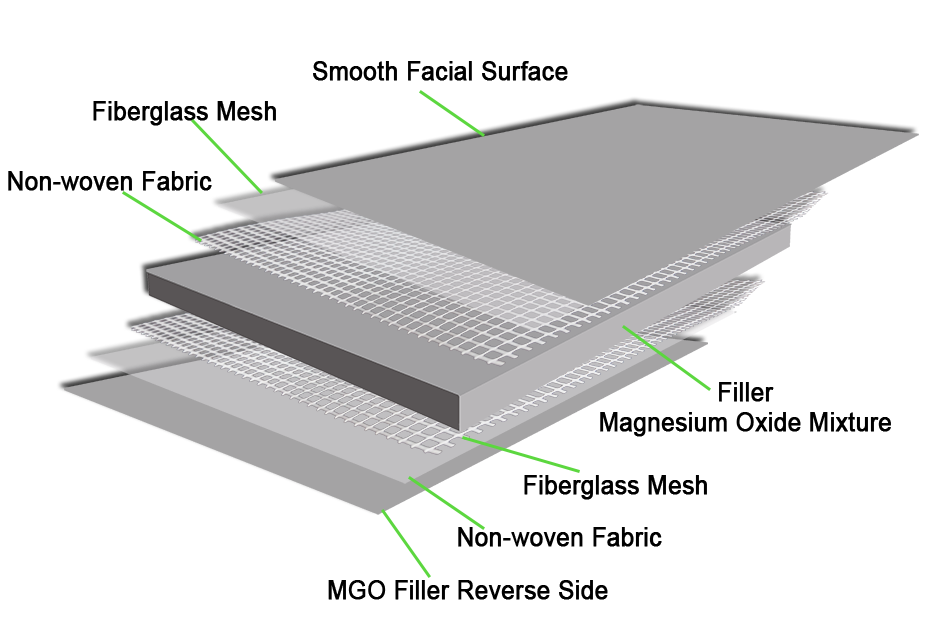

The hardwearing and extra strong hi-density FireCrunch K-Clad 1.15g/m3 Magnesium Oxide Sulphate ( MgSO4) cladding, means long term, very low maintenance, being a composite with only 2% organic wood chip for flexibility.

FireCrunch and FloodClad products provide protection from fires, floods, termites, impact, mould, mildew.

Ph 1300 933 102

technical@firecrunch.com.au

Royal Australian Navy installs FireCrunch K-Floor TG 19 at Garden Island Naval Base

Low net CO2 11.9 kg/m2 CFC products vs FireCrunch 0.60 kg/m2 95% less

The Garden Island, RAN naval base is now fitted out with specific areas requiring fire rated flooring systems and chose FireCrunch products to meet the requirement as FCA is NATA Labs CSIRO tested to AS1530-4 Australian Standards.

Installed by Brighton Construction NSW, this is one of many Government projects where FireCrunch has been selected for high fire performance, stability, density and high screw pull through requirements 7.9 kN. Other benefits are in water proofing and flood resistance where FireCrunch is an inert non-organic material, which termites cannot consume ,bacteria cannot survive on, and mould and mildew will not form.

The long terms benefits of multiple capabilities, low maintenance using FCA Magnesium Oxide sulphate composite (MgSO4) cladding are clear and with a very low CO2 5% net pollutive rate, are some of the reasons for Government and responsible construction choice as we move towards the 2023 Climate Accord targets.

Charles Sturt University awards FireCrunch the cladding supply contract for fire walls in its latest university development

Stage 2 of the Charles Sturt student accommodation units on campus Port Macquarie NSW

FireCrunch Australasia Pty Ltd commences supply of its products selected again for Stage 2 of the Charles Sturt student accommodation units on campus Port Macquarie NSW.

The install building contractor is Elicorp Pty Ltd Qld, in supply partnership with FireCrunch Australasia PL.

Stage 1 was completed in 2022 and the 2nd stage is now underway with completion later in 2023. FireCrunch was chosen, apart from it’s NATA labs CSIRO fire tested protection capabilities, but also for the low 5% CO2 emissions in manufacturing, in line with the University’s policies.

Port Macquarie is Charles Sturt’s newest campus. It includes brand-new student accommodation, state-of-the-art laboratories and facilities, as well as indoor and outdoor teaching spaces, so students can study in the sunshine. The campus uses natural building materials to echo the surrounding environment, and students have lots of options for places to study, relax and get together socially.